A CT Scan machine could consume as much energy in a day as an average household in India would, in an entire month. An average MRI scan could consume roughly 20 times energy as compared to an average CT scan. Radiology department in a hospital is a big consumer of electricity. A study published in Mar 2020 on energy and cost saving opportunities for CT and MRI operation concluded that there was considerable energy saving opportunities in radiology machines, especially during the idle time. This study observed that of the total energy consumption, nearly 2/3rd in CT scanners and 1/3rd in MRI machines was during non-productive idle or system off time. This seems like a lot of waste. Energy efficiency of modern CT Scanners is an important consideration in delivering Sustainable healthcare. The energy consumed by radiology equipment in hospitals may be very small compared to HVAC, lighting, pumping systems, kitchen, Laundry, lifts and other infrastructure, but any amount of energy saved is a contribution to the sustainability of the planet.

Let us look at what improvements in the past decade or so, have yielded energy efficient medical equipment, specifically CT Scanners.

Energy efficiency of modern CT Scanners

Over the past decade or so, advancements in technology have significantly improved the energy efficiency of medical imaging equipment like CT scanners.

Advances in detector technology and tube design have led to better image quality with lower radiation doses and reduced power usage. Cooling systems, hardware, software for 3D reconstruction, detector technology have all improved significantly. There is also increased focus on end-of-life energy efficiency.

If we were to compare a recent 16-slice CT scanner with a model from 10-20 years ago, the following can be observed:

Lower Power Consumption

The older models typically consumed around 30-50 kW during operation. The newer models have significantly reduced power consumption, often using around 20-30 kW.

E.g compare a Siemens Somatom Emotion 16 (Launched around 2005 and still popular in refurbished market) uses a 50KW generator vs Siemens Somatom Go Now (Launched around 2017), which uses a 32KW Generator.

Faster Image processing

The imaging process in older models was less efficient, often requiring longer scan times and more energy to achieve the desired image quality. Modern scanners are much faster. They can achieve the same or better image quality in shorter time frames, further reducing energy consumption. This is due mainly to far superior detector technology, as details further in the next section, below.

Enhanced Cooling Systems

Older scanners had less efficient cooling systems, leading to higher energy consumption for both the scanner and the cooling infrastructure. Improved cooling systems in modern CT Scanners and energy-efficient components reduce the overall energy footprint of the scanner and the cooling infrastructure. This is important because the cooling systems consume nearly 45% of the total energy consumed during imaging.

E.g compare a Siemens Somatom Emotion 16 tube heat capacity was 5 MHU, while Siemens Somatom go.Now can do the same job with a lower tube heat capacity of 3.5 MHU. The Max power rating of Somatom Emotion generator is 50kW, whereas Somatom Go.Now is 32kW. Lower the tube power, so lower the generator power. Power consumed by the computer system is also lower even though the processing capacity and speed is much higher.

Key Improvements

There are several key technical advancements that have in aggregate, resulted in energy efficiency of modern CT scanners mentioned above. Some of them are,

- Detector Technology: The industry has almost entirely shifted from Image intensifier (II) technology to flat panel detector (FP) technology. Flat Panel Detectors have far better detective quantum efficiency than Image Intensifiers. In other words modern detectors are more sensitive and efficient, allowing for lower radiation doses and reduced power requirements. They requires far less radiation dose as II (almost half), especially in magnification mode, to achieve the same image, if not better quality images. The FP detector is better in many other ways than Image Intensifier. An image intensifier may need servicing more often due to the higher radiation dose and has more parts requiring repair as compared to FP detector. A FP detector is far more compact and ergonomically better. This enables performing many procedures faster and easier. The Flat Panel Detector is also twice as good as II in terms of Field of View (FOV) and precision imaging. All these result in significantly faster, yet better imaging, yielding greater ease of use and energy efficiencies in the newer X-Ray equipment.

- Tube Design: Innovations in the X-ray tube design have improved energy efficiency and longevity. Lower tube power requirement has resulted in lower generator and cooling system capacity.

- Computing software & hardware advances: Enhanced software algorithms and computing capacity have improved higher data processing capability, image reconstruction speed and quality, reducing the need for repeat scans.

- Standby Modes: Modern CT scanners often have advanced standby modes that reduce power consumption when the machine is idle or off.

- Smart Energy Management: Many new CT scanners come with smart energy management systems that optimize power usage based on the specific imaging needs, further enhancing energy efficiency.

These advancements not only reduce the energy consumption of the scanners themselves but also decrease the overall environmental impact of healthcare facilities by lowering operational costs and carbon footprints.

Steps towards Sustainability

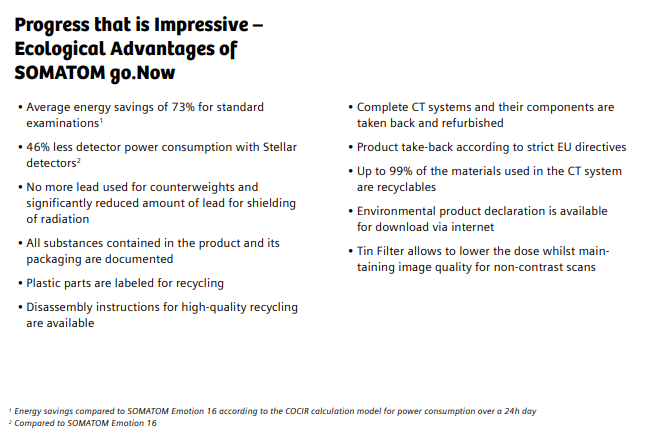

Medical equipment manufacturers are taking several steps towards sustainability, other than improved energy efficiency. Let us take a look at what Siemens Healthineer have shared as part of their Environmental Product Declaration (EPD) for SOMATOM go.Now below.

Today, there still is a demand for older used/ refurbished machines in smaller locations as the volume of cases may not justify big investments. However, one must be conscious that these older CT Scanners especially with lower slice capacity, while being cheaper in terms of upfront costs, take longer time to scan and reconstruct, consume far more electricity, use higher radiation dosages and end-up being costlier in the long run to both the owner and the planet. While buying a refurbished machine, make sure it is refurbished to as current energy efficiency standards as possbile.

—————————————————————————————————————————

PrimedeQ is an e-Marketplace for buying, selling, renting, servicing and spares of medical equipment. We offer all types of used / refurbished medical equipment , including cathlab, ECG machine and other diagnostic equipment, endoscopes, OT equipment, Laparoscopic Equipment, Lab equipment, X-Ray, TMT, anesthesia machine, ultrasound machines etc including physiotherapy and rehabilitation equipment (New & Used). We offer repair services for all types of medical equipment.

Contact us for any medical equipment requirements on 7019759765.