An X-ray machine repair may involve repair of any of its components such as x-ray tube, HV generator, image detection system, bucky table or wall stand, collimator or even control console.

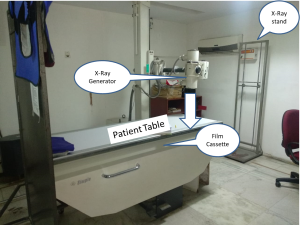

Main components of an X-Ray machine

An X-Ray machine is made up of several components, mainly, the X-Ray tube, High Voltage generator, cooling system, control console, collimator, image detection system (such as Film, Photographic plate or flat panel detectors) and others such Bucky Table, Chest/ wall stand etc. for positioning the patient. In case of C-Arm machine, the C-Arm movements and spot-film device are important components apart from the parts already mentioned above.

For more details on components of X-ray machine and its working, read https://www.primedeq.com/blog/how-does-an-x-ray-machine-work-what-are-the-main-components-of-an-x-ray-unit/

Most Common X-Ray machine Repair issues

An X-ray machine may fail or not function properly due to problems with any of its components. Lack of calibration is one of the most common and serious issues, not addressed well enough. As per NABH requirement in India, all medical equipment need yearly calibration at the minimum and Quality Assurance (QA) done at least every 2 years. Let us look at common problems with each of the X-Ray components.

1. Common causes of x-ray tube failure

Cathode filament failure, tube arcing, anode failure, Glass housing cracks/oil leak, aging of the x-ray tube components, Rotor bearing failure etc. are some of the main problems likely with X-Ray tubes.

Read more about causes of and options for X-Ray machine repair due to tube failure here – https://www.primedeq.com/blog/x-ray-tube-repair-common-causes-of-tube-failure/

2. Problems with High Voltage Generator

A large voltage spike caused due to tube arcing could result in damage of output components, such as capacitors and resistors and HV cable of an X-ray generator. Cable sockets at the junction of the HV Cables to the HV generator or the X-Ray tube end are other points of failure. The sockets could crack with stress of usage over a period of time, resulting in leaks and disconnections. Damage to HV transformer or filament transformer windings may also result in failure of HV generator. X-ray filament transformer/high tension transformer failure is also a problem in self-contained x-ray tube (stationary anode)

Read more about causes of HV X-Ray Generator failure and repair options here – https://www.primedeq.com/blog/high-voltage-x-ray-generator-failure-and-repair/

3. X-Ray machine control panel/ console repair issues

The control panel captures user inputs for mA, KV (exposure settings) or program and environment. Hand switch and/or foot switches are also used in various X-Ray modalities. Usage over time may result in break/ wear and tear of membrane keypad/ membrane keyboard, skin sheet, switches, knobs. Power supply, control or other boards may need repair or replacement.

4. Common problems with Collimator in X-Ray machines

A collimator helps control radiation output from X-Ray generator. Collimation helps in improving image quality by minimising scatter radiation and also preventing unnecessary exposure outside the area of interest on the patient. Collimators are made of lead shutters, most commonly 4 blades with 2 motors (or if IRIS collimator 8 blades with 4 motors). The most common reasons of collimator malfunctioning are related to motors or calibrations.

5. Repair issues with Bucky Table or Wall stands

Bucky Table and Wall stands are used to position patients and place the photographic plates for image capture. The table and stand are normally capable of up/down and tilting movements so as to position the patient appropriately for exposing the required anatomy. Difficulty in movement of the table / stand can stymie the entire X-ray procedure. The same problems regarding tilts and movements may occur with overhead stands, consisting of tube and detector.

6. Image detection system in X-Ray machine repair

The most commonly used image detection systems today are photographic plate or Flat panel detectors. Film processing is quite outdated. Most common problems with CR based detection systems is erasure not happening properly, defective laser, defective pick-up device, defective monitor display or simply calibration issues. If using a detector, again common problems are power supply issues, defective pixels, deteriorating flash, bad fibre optic cables etc.

Should you face any problems with your X-Ray machines such as arcing issues, faulty bucky table, defective hand switch, HV transformer failure or other problems in the X-Ray tube or any other component of the X-Ray machine as discussed above, contact us! PrimedeQ can assist you with spare parts, HV generator repair, cable sockets replacement, HV Cable repair/ replacement, transformer windings, PCB replacements, console membrane replacements, x-ray tube oil re-filling, vacuum treatment services and several other types of X-Ray machine repair services or calibration and QA services.

Need help with troubleshooting X-Ray machine related problems? Check this out –

https://www.youtube.com/watch?v=DSX0ygI0fZs

—————————————————————————————————————————

PrimedeQ is an e-Marketplace for buying, selling, renting, servicing and spares of medical equipment. We offer all types of used / refurbished medical equipment , including used X-Ray or C-Arm machines, ultrasound machines and surgical equipment, endoscopes, OT equipment, Laparoscopic Equipment, Lab equipment, TMT, ECG, anesthesia machines etc. We offer repair services for all types of medical equipment including Lab equipment, Ophthal equipment such as AR, slitlamp, ENT equipment like microdebrider, laparoscope , x-ray tube, rigid and flexible endoscopes as well as EUS (Endoscopic Ultrasound Units) and ultrasound probe etc.

Contact us on +91 8971223957/ 7019759765 or [email protected]

https://in.linkedin.com/in/shanthi-mathur-ab07838